Too much of the rubbish we generate each year is still disposed of in non-environmentally friendly ways as opposed to being recycled. This has resulted in toxic farmland, record levels of air pollution, contaminated rivers and oceans, clogged valleys and much more. Most of the industrial, commercial and personal waste sent to incineration plants, seafills and landfill sites each year contains valuable products. It used to be too expensive to recover all of those products from waste materials, but the pyrolysis plant has now made it profitable to extract valuable resources from waste, including from plastic waste, rubber waste, and oil sludge.

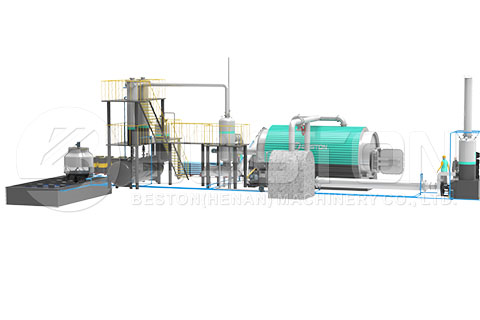

Oil Sludge Pyrolysis System

In an oil sludge pyrolysis setup, oil sludge is heated to a high temperature (~425C) in an oxygen-absent reactor. The oil sludge can’t burn and smoke because it has no access to oxygen, which is needed for combustion. Instead, it vaporizes and travels into a condensing tube network where it is turned to high-grade liquid fuel oil. The end products from the process include combustible gas (which is used as fuel for the reactor furnace), fuel oil and carbon black. Each one of those commodities is easy to sell for healthy profits in the international market space.

An oil sludge pyrolysis plant is perfect for separating valuable oil from water, sand, stone, dirt, and many other impurities. Everyone knows that lots of oil sludge are formed during oil exploration and on oil drilling sites, so it’s great that we now have a pollution-free way to recover oil from the sludge. There is now no excuse for businesses to continue disposing of oil sludge in ways that pollute the environment.

A fully continuous oil sludge pyrolysis plant typically comes equipped with a conveyor system, which is used to move waste unloaded by oil sludge dumper trucks into the pyrolysis reactor automatically. Unlike batch pyrolysis plants, a fully continuous plant does not require a cool-down period between different waste loads, which means that it is much more energy-efficient. Continuous pyrolysis system has automatic feeders and dischargers connected to the reaction chamber and they can operate 24/7.

Oil Sludge Pyrolysis Plants For Sale

There are many manufacturers in the oil sludge pyrolysis plant industry. This means that buyers have a large variety of different plant types to choose from and they can also take advantage of competitive pyrolysis system prices. In general, ordering from a leading manufacturer in the industry, like Beston, is the best option for businesses. Beston has distribution centers in lots of global locations, so those looking to process oil sludge waste in all countries should be able to find Beston pyrolysis plants for sale.

One of the main reasons to buy from an established manufacturer it that you can avail of expert plant installation services and operator training. Customer service agents from bigger suppliers also tend to speak a range of different languages, so you don’t have to worry about any communication issues. Furthermore, pyrolysis plants from top-rated manufacturers typically come with lengthy service guarantees.