When it comes to sustainable waste management practices, tyre pyrolysis has emerged as a promising solution. This innovative technology allows for the conversion of used tires into valuable products such as fuel oil, carbon black, and steel wire. However, before diving into this eco-friendly venture, it is crucial to understand the cost implications associated with establishing and operating a tyre pyrolysis plant. In this article, we will explore the various cost factors that need to be considered for a successful and profitable operation.

Capital Investment

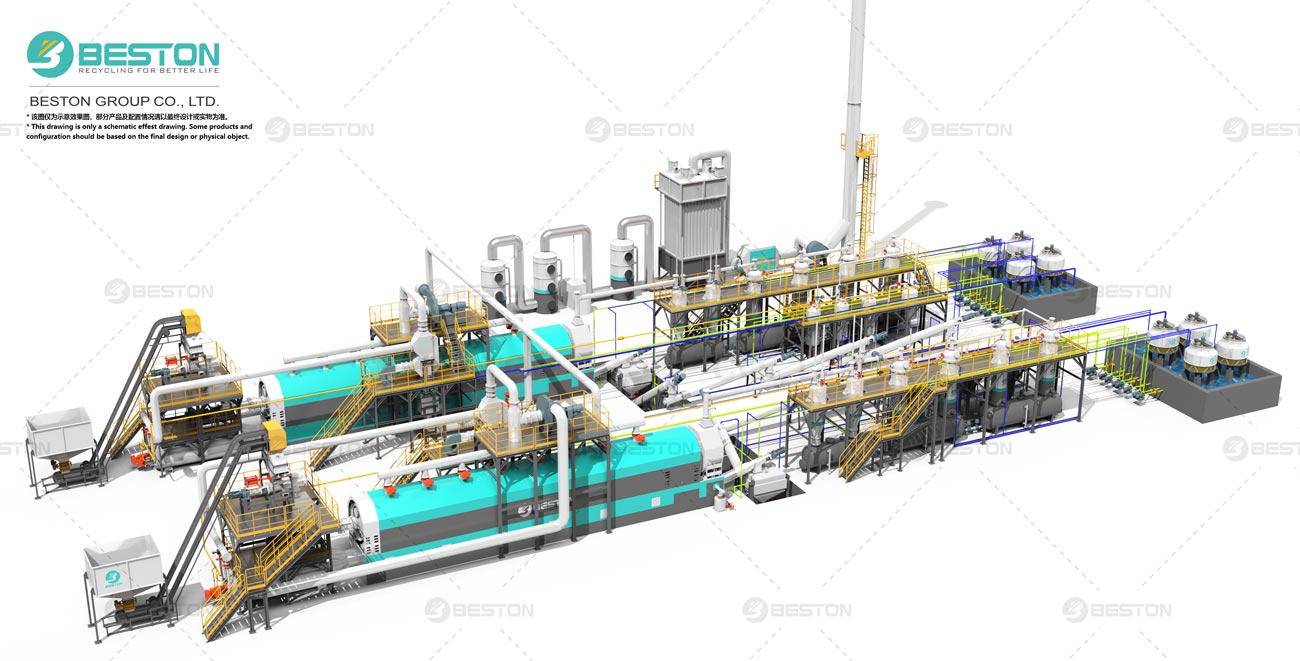

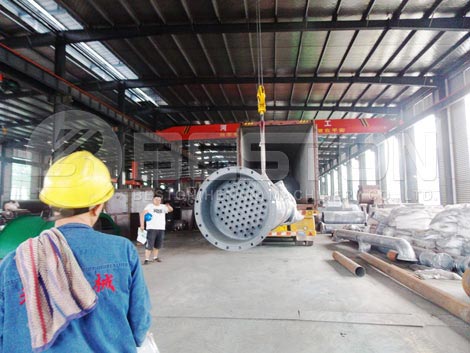

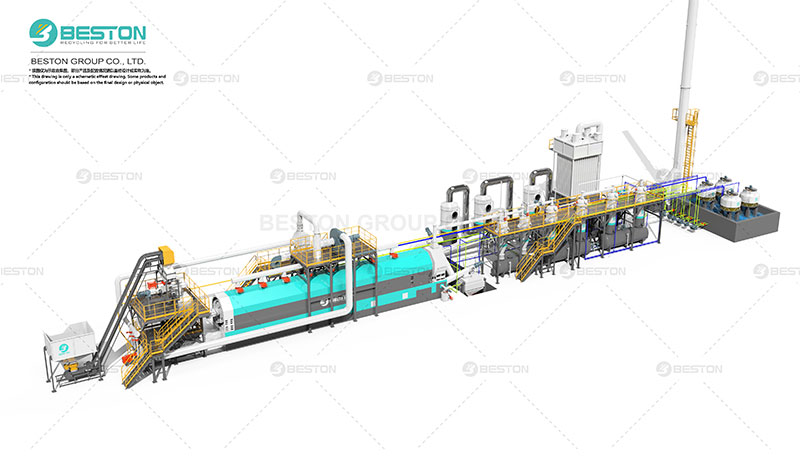

Setting up a tyre pyrolysis plant requires a significant capital investment. This includes the initial setup tyre pyrolysis cost, which involves acquiring land, obtaining permits, and conducting feasibility studies. Additionally, the purchase of machinery and equipment, such as pyrolysis reactors, condensers, and oil tanks, constitutes a substantial portion of the capital investment. Furthermore, infrastructure and site development costs, including construction, electrical connections, and waste storage facilities, must be taken into account.

Operational Costs

Once the plant is up and running, several operational costs come into play. Raw material acquisition is a primary expense, as the plant requires a steady supply of discarded tires. The cost of procuring these tires may vary depending on factors such as market conditions and transportation logistics. Labor expenses encompass salaries and wages for skilled workers, plant operators, and maintenance personnel. Energy consumption, particularly during the pyrolysis process and auxiliary operations, contributes significantly to the operational costs. Lastly, maintenance and repair costs should be considered to ensure the plant operates smoothly and efficiently.

Compliance and Certification

Compliance with environmental regulations and obtaining necessary certifications are crucial aspects of operating a tyre to oil plant. Adhering to stringent environmental standards, including emissions control and waste disposal protocols, requires investments in monitoring equipment, pollution control systems, and proper waste management infrastructure. Certification requirements, such as ISO and quality management certifications, add to the overall cost of running the plant. It is essential to factor in these compliance and certification costs to maintain legal and ethical operations.

Financial Considerations

To gauge the viability of establishing a tyre pyrolysis plant, financial considerations play a vital role. Determining the return on investment (ROI) is crucial for assessing the profitability of the venture. The revenue generation potential, primarily from the sale of fuel oil, carbon black, and steel wire, should be carefully evaluated. Additionally, financing options and interest rates affect the overall cost of the project, as different sources of funding come with varying terms and conditions. Conducting a comprehensive break-even analysis will provide insights into the time required to recover the initial investment and start generating profits.

Long-term Sustainability

Beyond the initial investment and operational costs, long-term sustainability factors into the overall cost of a pyrolysis plant for sale. Waste management and disposal costs must be considered, as the plant generates byproducts and residues that require proper treatment and disposal. Implementing effective recycling and resource recovery measures can reduce waste management expenses and enhance the overall sustainability of the plant. Additionally, market demand and price fluctuations for the derived products can impact profitability. Keeping a close eye on market trends and maintaining flexibility in product pricing can help mitigate potential financial risks.

In conclusion, the cost of a tyre pyrolysis plant involves a comprehensive analysis of capital investment, operational expenses, compliance and certification requirements, financial considerations, and long-term sustainability factors. The above factors determine how to choose a suitable manufacturer. Beston Group should be your first choice

Understanding and carefully assessing these cost factors are crucial for making informed decisions and ensuring the financial success of a tyre pyrolysis venture. By considering all aspects, both in terms of short-term expenses and long-term prospects, entrepreneurs can embark on a journey towards sustainable waste management and contribute to a greener future.