In the realm of charcoal production, the debate between modern charcoal machines and traditional charcoal kilns continues to intrigue enthusiasts and industry professionals alike. With the advent of technology, modern methods employing coconut shell charcoal making machines have emerged, challenging the time-honored techniques of traditional charcoal kilns. This article delves into the intricacies of both approaches, exploring their processes, efficiencies, environmental impacts, and overall effectiveness.

Traditional Charcoal Kiln: A Time-Honored Craft

Traditional charcoal production equipment involves the use of kilns, often constructed from bricks or earth mounds. The process begins with the stacking of wood or coconut shells in a pyramidal fashion within the kiln. This arrangement allows for proper airflow, essential for the controlled burning of the biomass. Once loaded, the kiln is ignited, initiating the carbonization process.

The combustion of the organic material within the kiln leads to the expulsion of volatile compounds, leaving behind a residue rich in carbon—the charcoal. This slow pyrolysis process typically takes several days to complete, during which meticulous monitoring is necessary to prevent over-burning or incomplete carbonization.

Pros and Cons of Traditional Charcoal Kilns

Pros:

- Low Initial Investment: Traditional kilns can be constructed using locally available materials, minimizing initial capital outlay.

- Suitable for Small-Scale Production: Ideal for artisanal or small-scale operations due to their simplicity and ease of construction.

Cons:

- Time-Intensive: The process of carbonization in traditional kilns is labor and time-intensive, often requiring several days to yield usable charcoal.

- Environmental Impact: Inefficient combustion in traditional kilns leads to higher emissions of greenhouse gases and pollutants, contributing to environmental degradation.

- Inconsistent Quality: Variability in temperature and airflow within the kiln can result in inconsistent charcoal quality.

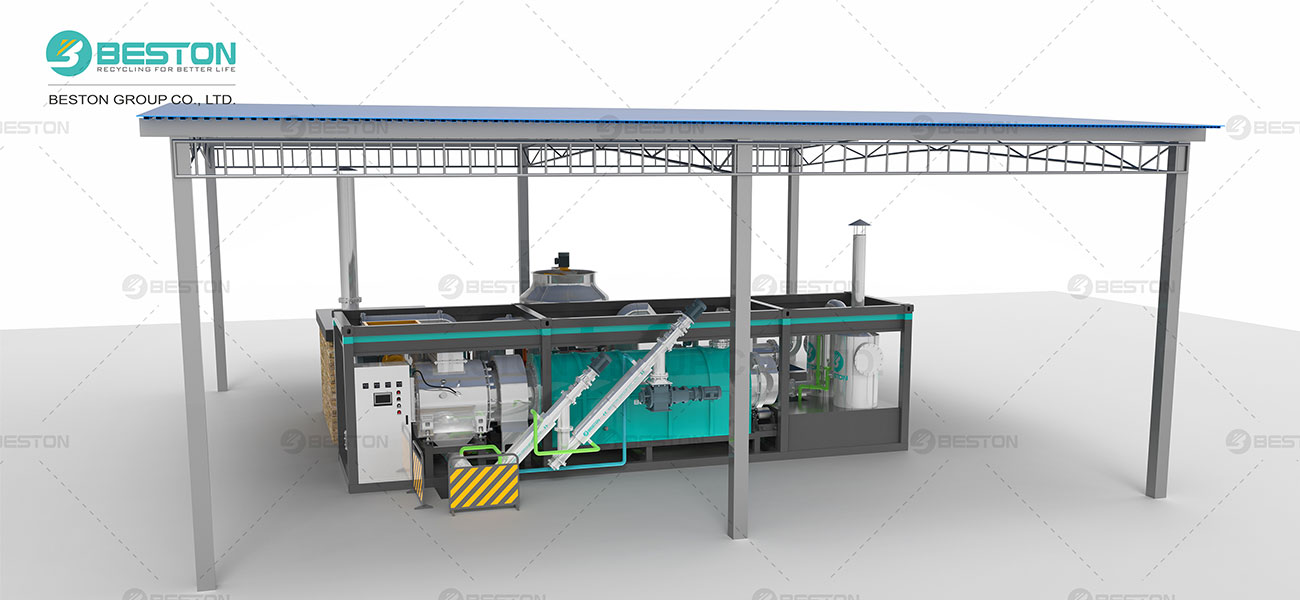

Modern Charcoal Machine: Precision and Efficiency

In contrast to the labor-intensive nature of traditional methods, modern coconut shell charcoal making machine offers precision, efficiency, and scalability in charcoal production. These advanced machines utilize cutting-edge technology to streamline the carbonization process, maximizing output while minimizing environmental impact.

How Modern Charcoal Machines Work

Modern charcoal machines operate on the principle of pyrolysis, a thermochemical decomposition process that occurs in the absence of oxygen. Coconut shells, the raw material of choice for many modern operations due to their high carbon content and sustainability, are fed into the machine’s chamber.

Within the chamber, the coconut shells undergo controlled heating, gradually transitioning from organic matter to charcoal. The absence of oxygen prevents combustion, ensuring that the carbonization process occurs efficiently and without the release of harmful pollutants.

Once carbonization is complete, the machine’s automated system facilitates the collection and packaging of the finished charcoal, ready for distribution and use.

Pros and Cons of Modern Charcoal Machines

Pros:

- High Efficiency: Modern charcoal making machine can process large quantities of coconut shells in a fraction of the time required by traditional methods, increasing overall productivity.

- Consistent Quality: Automated controls ensure uniform temperature and airflow throughout the carbonization process, resulting in charcoal of consistent quality.

- Environmental Sustainability: By minimizing emissions and maximizing resource utilization, modern charcoal machines offer a more environmentally sustainable alternative to traditional kilns.

Cons:

- Higher Initial Investment: The upfront cost of acquiring and installing a modern charcoal machine may be prohibitive for small-scale producers or artisanal operations.

- Maintenance Requirements: Like any machinery, modern charcoal machines require regular maintenance and occasional repairs to ensure optimal performance.

- Dependence on Technology: Reliance on technology means that interruptions in power supply or equipment malfunction can halt production. To learn more about advanced charcoal production technology, visit: https://bestonmachinery.com/

Conclusion: Striking a Balance

In the ongoing debate between modern charcoal machines and traditional charcoal kilns, there is no one-size-fits-all solution. Both approaches have their merits and drawbacks, catering to different scales of production, resource availability, and environmental priorities.

While traditional kilns offer a time-honored craft and low entry barriers, they are often limited by inefficiencies and environmental concerns. On the other hand, modern charcoal machines represent a leap forward in terms of efficiency, consistency, and environmental sustainability but require a significant initial investment and technological expertise.

Ultimately, the choice between modern machines and traditional kilns hinges on a careful consideration of factors such as production scale, available resources, environmental impact, and long-term goals. By striking a balance between tradition and innovation, charcoal producers can optimize their operations for efficiency, quality, and sustainability in the ever-evolving landscape of charcoal production.