Agricultural residues such as straw, rice husk, bamboo offcuts, and orchard prunings are increasingly viewed as underutilized carbon resources rather than disposal burdens. Through thermochemical conversion, these lignocellulosic materials can be transformed into stable charcoal products with defined physicochemical properties. The charcoal making machine provides a controlled pathway for this conversion, enabling consistent output, predictable performance, and scalable deployment across agricultural regions.

Feedstock Characteristics and Carbonization Potential

The heterogeneity of agricultural waste demands precise process control. Straw presents low bulk density and high ash content, while bamboo exhibits dense fiber bundles and elevated fixed carbon potential. Equipment design must account for volatile release profiles, moisture variability, and particle size distribution. A straw charcoal machine typically integrates pre-drying and staged heating to mitigate rapid devolatilization. In contrast, a bamboo charcoal making machine emphasizes uniform heat penetration to preserve pore structure and enhance mechanical integrity of the final charcoal.

Thermochemical Conversion Pathways

At the core of modern charcoal production lies biomass pyrolysis equipment operating under oxygen-limited conditions. Thermal decomposition proceeds through dehydration, depolymerization, and aromatization phases. Hemicellulose degrades first, followed by cellulose, with lignin contributing to long-chain aromatic networks. Temperature ramps, residence time, and heating rates dictate charcoal yield and surface chemistry. Slow pyrolysis favors higher solid yields, while controlled intermediate regimes balance energy recovery with carbon retention.

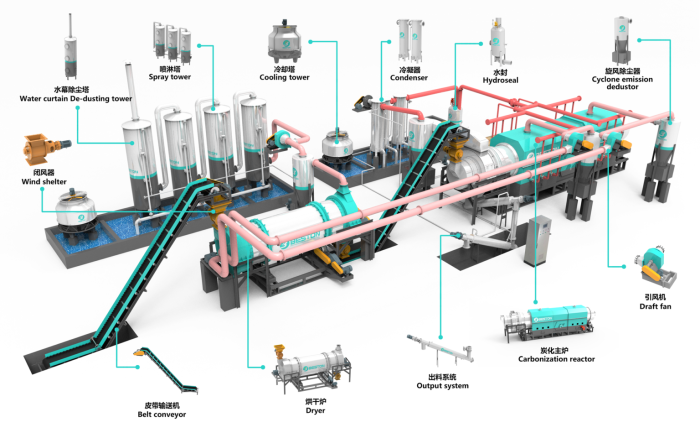

Reactor Architecture and Process Stability

The biochar reactor functions as the central processing unit, translating thermal input into material transformation. Fixed-bed, rotary kiln, and continuous screw configurations are selected based on throughput and feedstock behavior. Advanced reactors employ zoned heating, negative pressure control, and automated feeding to stabilize reactions. Off-gases are recirculated for thermal efficiency, reducing auxiliary fuel demand. This closed-loop operation improves carbon efficiency and lowers operational variability.

Product Performance and Application Scope

Charcoal derived from agricultural waste demonstrates tailored porosity, alkaline buffering capacity, and adsorption affinity. These attributes enable deployment in soil amendment, odor control, water filtration, and metallurgical reductants. Bamboo-derived charcoal often exhibits higher compressive strength and microporosity, while straw-based charcoal offers rapid reactivity and nutrient interaction. Process tuning allows producers to target specific end-use requirements without altering core machinery.

Environmental and Operational Implications

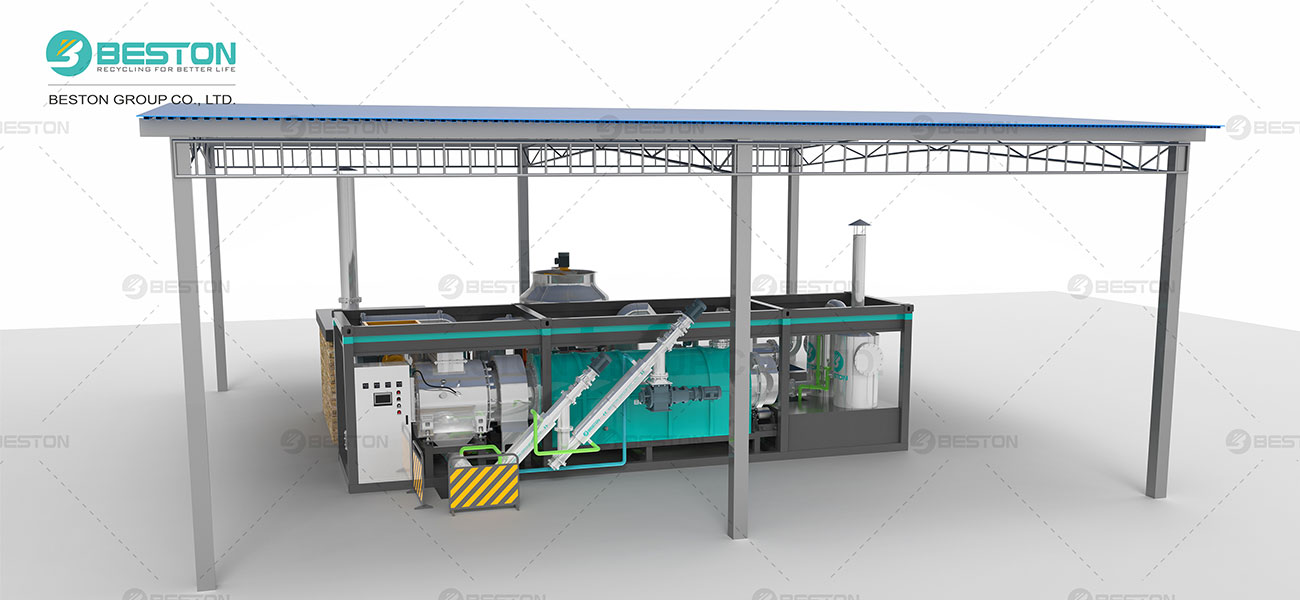

Beyond product value, the bamboo charcoal making machine contributes to residue management and emissions reduction. Converting open-field waste into stable carbon mitigates particulate release and methane formation. Integrated systems align with circular economy principles by transforming waste streams into durable materials. Operationally, modular equipment footprints support decentralized installation near feedstock sources, reducing logistics complexity and improving overall system resilience.

In sum, the convergence of feedstock science, reactor engineering, and process control defines the effectiveness of agricultural waste carbonization. Through disciplined application of pyrolysis principles, charcoal production evolves from a traditional practice into an industrially reliable, resource-efficient operation.