If you are wondering about egg tray machine Philippines prices, you have come to the right place. The average price of an egg tray making machine in the Philippines is between $8,000 to $70,000. In fact, the more features of the product, the expensive it’s going to be. With a host of brands and models of egg tray machines in the Philippines, choosing the best machine is not easy. You should perform extensive research before buying the best egg tray machine for your business. This article provides information on what you should look for when shopping for a high-quality egg tray machine in the Philippines.

If you have access to a steady supply of waste paper, you should definitely invest in a small egg tray machine to earn money by selling paper pulp egg trays. In fact, paper egg trays are in high demand across the Philippines because it’s eco-friendly compared to plastic egg trays. Most poultry farm owners and other businesses are looking for paper egg trays to minimize the effect on the environment. Paper egg trays are manufactured in an eco-friendly way, and you will be doing your part towards the environment when you invest in a egg tray making machine China.

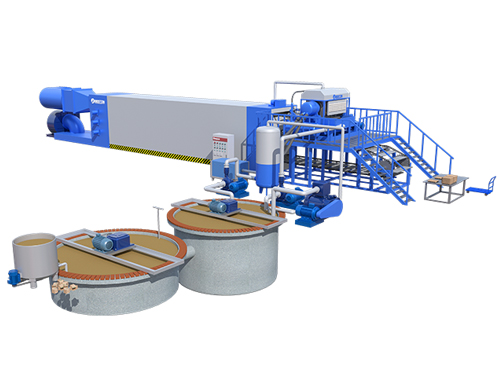

The egg tray machine answers two questions at the same time and lets you make a good profit by turning waste paper into egg trays. The machine takes waste paper, cartons, and newspaper as raw materials and makes egg trays. It increases the reusable value of water paper and brings additional profits for your business. On the other hand, an egg tray machine is a simple unit to deliver, install, and operate. The basic parts of an egg tray machine are the pulping, forming, and drying systems: https://www.bestongroup.com/egg-tray-machine/dryer/. The pulping system includes the hydraulic pulper, stirred tank, pulp pond beater, pulp pool, and water pool. Most machines have an automatic integrated pulping system that helps reduce floor space and labor costs. It helps improve pulping efficiency and enable easier delivery.

The forming system has an air compressor, a vacuuming pump, a molding machine, and a water pump. In fact, the machine has a forming mold and a transfer mold. The drying system is the other basic part of an egg tray machine. Once molded, egg trays should be fired before they are packed. There are different types of drying systems in egg tray machines such as natural drying in the sun, brick drying with conveyor belts, brick drying with carts, and metal drying. The drying efficiency may differ depending on the type of drying system you opt for. You need to inspect every egg tray making machine before buying the right one.

Are you planning to buy an egg tray machine in the Philippines? If so, you are in the right place. Egg trays are in high demand across the Philippines. That’s why you should invest in a quality egg tray making machine at an affordable price. The average egg tray machine price in Pakistan is around $8,000 to $70,000. The aforementioned article provides information on the egg tray machine Philippines prices.