Efficient and productive pyrolysis palnt could net your business plenty of profits. However, the key to producing lots of revenue through pyrolysis is securing high-quality plants. The only way you can get great plants is by finding a trustworthy manufacturer. Here’s how you should go about finding the best pyrolysis plant manufacturers.

The pyrolysis industry is incredibly complex, which is why you only want to work with manufacturers that have extensive experience producing plants. Working with manufacturers that don’t understand the complexities within the pyrolysis market will likely lead to troubles for you and your company. Luckily, there are plenty of manufacturers available for you to choose from that have lots of experience making these types of plants.

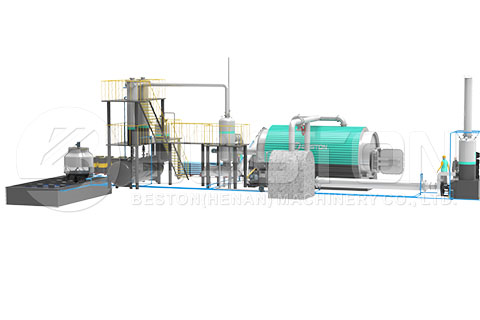

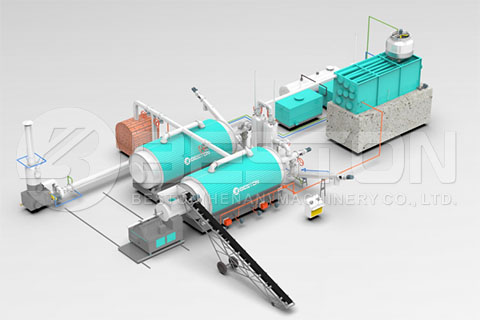

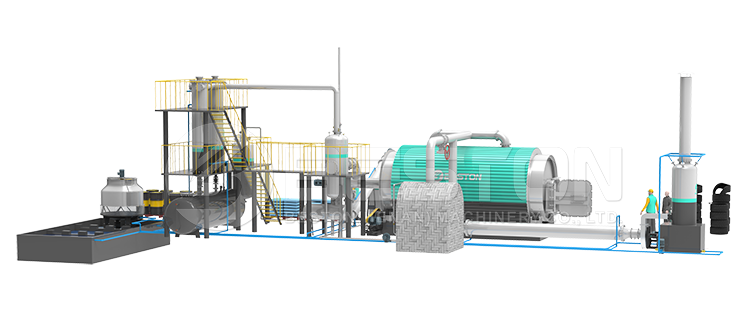

Choose manufacturers that can produce a huge selection of different pyrolysis plants. Some plants are more suitable for your needs than others. You and your team should look for pyrolysis plant manufacturers that can give you a huge selection of plants that meet each and every specification you might have. If you can secure plants that are highly optimized to your business operations, you can expect to achieve great profits. Here is a website you can find more models for sale, as well as the pyrolysis machine cost information: https://mswrecyclingplant.com/pyrolysis-plant-cost/.

Don’t buy from pyrolysis plant manufacturers that charge too much for their plants. It’s important that you get as much value for money from your investment as possible. Conduct price comparisons with other pyrolysis plant producers to see whether or not the companies you’re considering are charging a fair price. If you buy a plant that is too expensive, it will take a lot more effort to get a decent return on investment. Ideally, you should find a plant that is not only efficient but also very cheap.

You must discuss all the details of delivery with any pyrolysis plant manufacturers you’re thinking of buying plants from. Delivery is important as you should get your assets promptly after you purchase them from a manufacturer. Waiting months for delivery could mean major issues for your business. Great manufacturers understand that simply producing a great plant isn’t enough, they also need to secure reliable logistical routes for delivery. Beston Machinery in China is highly recommended.

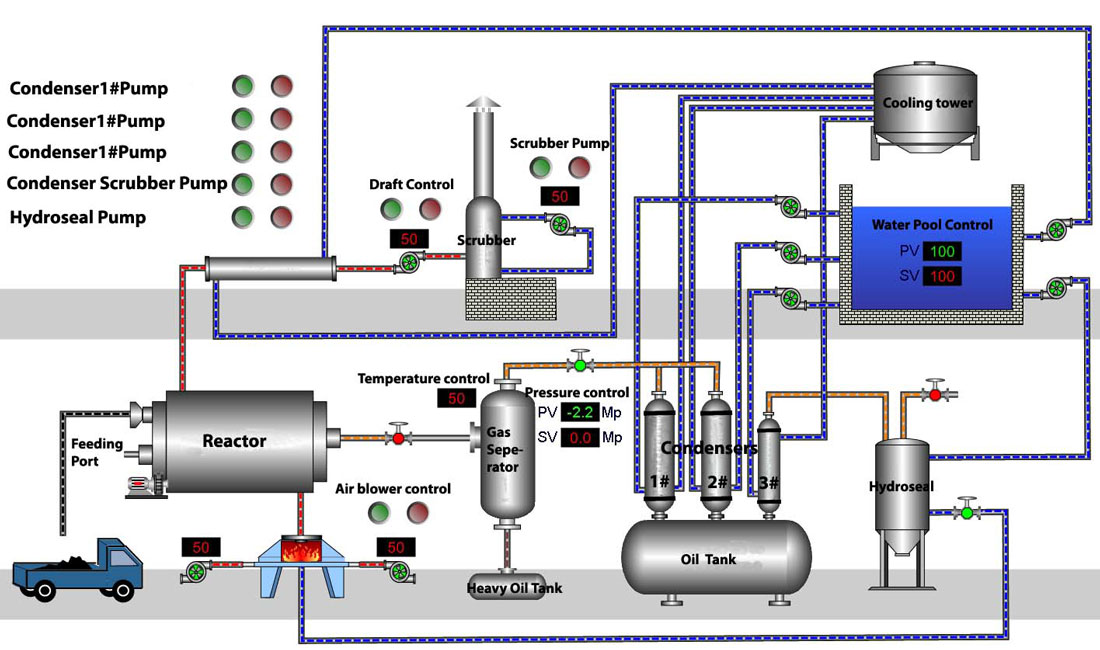

If you currently operate a highly specialized form of pyrolysis, you should seek modifications to your order. Many of the best pyrolysis plant manufacturers can easily adjust their products and designs to suit your needs. You should enquire with the various plant manufacturers you believe produce high-quality plants to see whether or not they are open to modifying their products for you. Also, you should talk with your engineers to see whether or not any modifications could lead to a tangible increase in efficiency and profits. Besides, you can find different types pyrolysis plants for sale, such as batch or continuous plant. Fully continuous pyrolysis plant is more automatic and efficient, which is preferred by many investors. You can check the link here for more details: https://mswrecyclingplant.com/fully-continuous-pyrolysis-plant/.

If you’re having difficulties finding great manufacturers, don’t be afraid to ask for recommendations. Lots of business managers in the pyrolysis sector have worked with countless manufacturers. If you ask them for their thoughts and opinions, they will likely recommend a few manufacturers that they believe are outstanding. From there, you should consult with these various manufacturers to see whether or not they are suitable. Hopefully, by the end of the process, you would’ve found a trustworthy manufacturer.