Most new buyers have a problem finding charcoal production equipment for sale. In fact, some of these buyers make costly mistakes. If you do not know where to find charcoal production equipment, you may spend several days, weeks, or even months looking for the right charcoal making machine.

By the way, there are so many manufacturers, companies, suppliers, and even websites selling the equipment, so the problem is finding the right seller. If you have a problem locating the right seller, continue reading.

1. Find Charcoal Production Equipment for Sale On The Internet

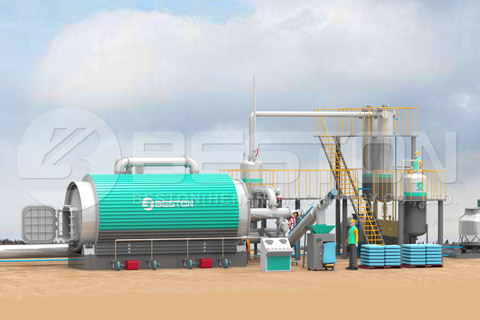

Hate doing your research offline? Why not use the internet. There is free information online. By the way, the rise of online stores is because a lot of people are no longer afraid of buying products online. So, there are reputable online stores selling charcoal production equipment. Beston will give you some information about biomass pyrolysis plant cost.

How do you select the right online store? Check how long the store has been in this business and the reputation of the store. To get quality equipment, you need to use reputable stores. Avoid new online stores because they do not have enough experience.

You can save money by buying the equipment online. How? Compare the prices of different online stores. Then, select an online store that has cheap prices. Select a well-established and reputable online store that suits your budget.

2. Charcoal Production Equipment Manufacturers

Manufacturers make charcoal production equipment. However, finding the right manufacturer is the hardest part because there are several manufacturers. Most of these manufacturers make equipment that looks exactly the same.

How do you pick the right manufacturer? Find out how long these manufacturers have been making sawdust charcoal making machine. The best ones have several years of experience. And they have the best equipment in the market.

Avoid inexperienced manufacturers because it is hard to know the quality of their charcoal production equipment. By the way, do not select a manufacturer that has expensive prices if you cannot afford their prices. Choose an experienced manufacturer.

3. Ask Around About Machines

If you have a charcoal making company, it means you have been in this industry for some time. You may know a lot of people in this industry. Do not look at these people as your competitors. Some of these people are friendly. And they are ready to help.

In fact, some people have more experience than you. They have bought and used different charcoal production equipment. So, they know where to find the best equipment. When you talk to these people, they recommend the right seller that has high-quality charcoal production equipment for sale, like Beston.

In addition, some people can help you avoid choosing the wrong seller. They have used several sellers, so they know a lot of sellers. If you tell them you want to use a certain seller, they may tell you to avoid that seller because they have had a bad experience with that seller.

You now know where to find charcoal production equipment for sale. Use the information in this article to make an informed decision. And buy the equipment from a trustworthy and well-established seller.