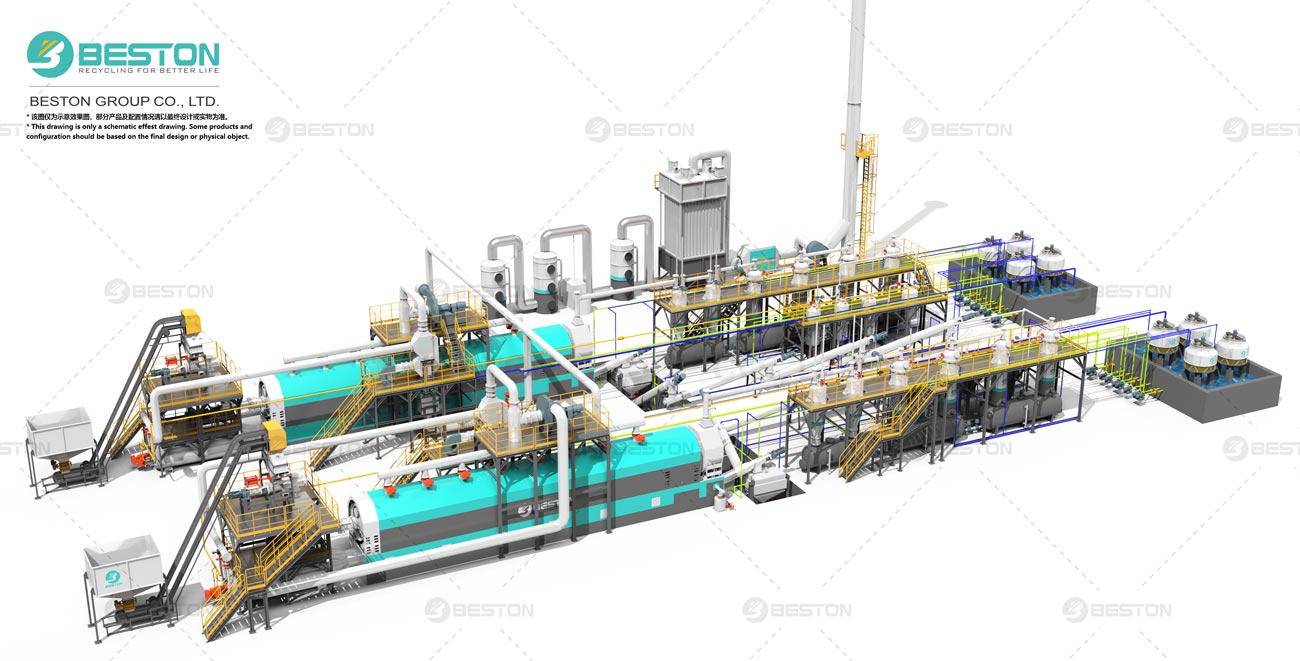

The tyre to fuel recycling plant also goes by the name of a waste-tyre pyrolysis plant. These plants adopt the most current pyrolysis design and technology, which guarantees safety and efficiency.

Advantages Of The Tyre To Fuel Recycling Plant

With the adoption of the latest technology in pyrolysis, the waste tire to fuel machine offers environment-friendly, energy-saving, safe, and easy operation features.

#1 Easy Operation

The discharging and feeding operations are automated which makes these plants highly convenient when it comes to how you operate them.

#2 Safety

These plants come equipped with state-of-the-art safety devices and mechanisms, including safety valves, thermometers, pressure gauges, and electric control systems. The vacuum and hydro seal system are what stop the exhaust gas from flowing back into the reactor and the condensers. This prevents unnecessary accidents from occurring in these waste tyre recycling plants.

#3 Energy Saving

The gas that does not convert into liquid oil when placed under pressure is further recycled by providing heat to the reactor in the form of fuel. Gas that is generated through the process of pyrolysis has a higher caloric value which helps to save a lot more energy throughout the working process.

#4 Environment Friendly

Each part in a tyre to fuel recycling plant is well-sealed which means any type of air leakage or accidents will be avoided. The dedusting system involves three steps that are used for dedusting the hot dark smoke that is generated from the reactor. This ensures that the gas that is released is pollution-free and that it can then be directly and safely discharged (into the air). View this report – https://bestonmachinery.com/tyre-pyrolysis-plant/project-report/.

What Is The Production Process Of Waste Tyre To Fuel?

The first step of the process involves placing the waste tyres into a reactor through an automatic feeder. The reactor is heated with a fuel such as natural gas, oil, wood, or coal.

Once the temperature of the reactor has reached around 250 degrees Celsius, oil gas is generated. The oil which is now in a liquid form will be cooled in a cooling-system which is then collected in an oil tank.

The combustible gas that cannot cool under normal pressure will then be recycled once again to provide heat to the reactor. This process saves a lot of energy and is much kinder to the environment.

The smoke that is produced during the process of heating the reactor achieves international emission standards thanks to the dual dusting removal and desulfurization device.

The last step of this process is where the “fuel oil” is produced and the temperature of the reactor is reduced. At the same time, another product known as carbon black is automatically discharged.

The entire operation process involved converting waste tyres to fuel is environment-friendly, energy-saving, and efficient. If you run a business that deals with waste tyres, one of the mobile pyrolysis machine is one of the best options to turn your waste into profits and to help the environment by processing this waste so that it does not land up in landfills.