A charcoal making machine can be used to produce wood-fired fuel from waste. The process of charcoal making is an eco-friendly process that can generate multiple incomes. The machine can produce high-quality charcoal in as little as 30 minutes. It is also a renewable resource that does not produce pollution. Charcoal making machines are available in various price ranges, from inexpensive to expensive. Here are some features to consider before buying one:

Beston Charcoal Making Machine

The Beston charcoal making machine is a biomass burning machine. It converts waste biomass into biochar. The waste biomass may be coconut shell, sawdust, wood, palm kernel shell, rice husk, etc. Biochar is highly valuable, and is widely used in industrial and agricultural sectors. Its efficient working helps to improve the rate of waste recycling and promote economic development. Besides generating biochar, this machine also helps to reduce environmental pollution.

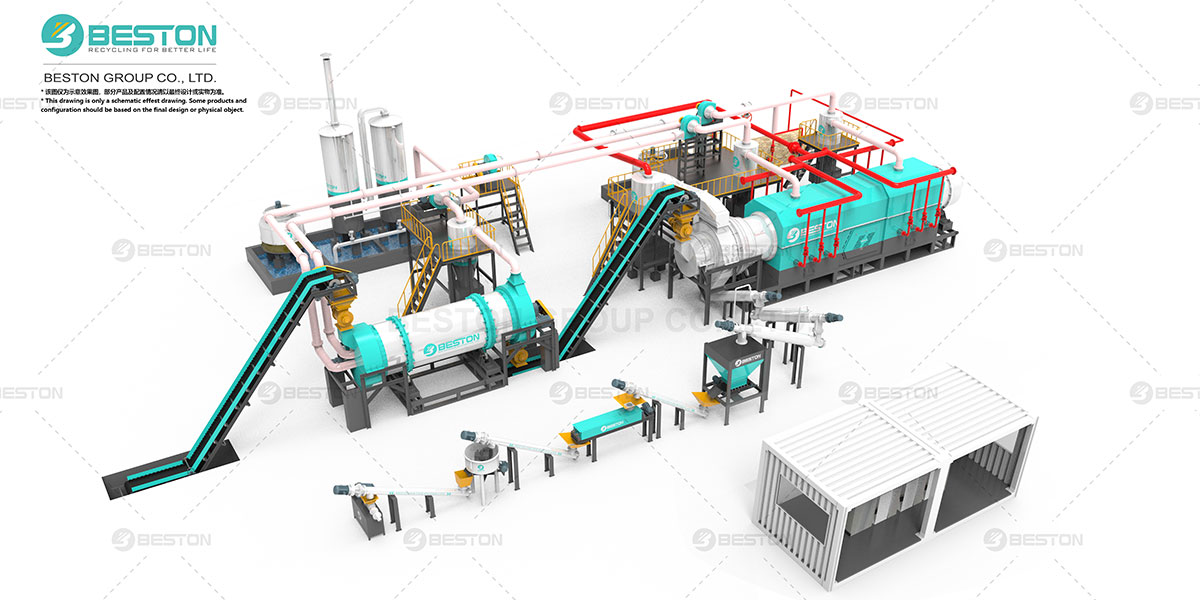

Among the many features of the Beston charcoal making machine, the carbonizing furnace is the highest-quality and fastest-in-class. Its advanced design makes it possible to meet all carbonization requirements, while at the same time reducing energy consumption. This machine is comprised of many supporting devices. It is equipped with a chassis, drier, carbonizing furnace, and exhaust gas recycling. The machine also features a reliable casing outside the charcoal furnace, which prevents workers from directly touching the charcoal furnace.

Processes Used In A Charcoal Making Machine

The carbonization furnace of a biochar machine works by burning wood and then generating CO and CO2. This produces CO and the gaseous products acetic acid and methanol. At a temperature of 270 to 300 deg C, the wood undergoes exothermic decomposition. This causes the formation of plant tar and pyroligneous extracts. Charcoal produced at this temperature contains a high content of volatile organic compounds. At around 800 degrees C, the fixed carbon content reaches 82 to 84%.

Charcoal is an excellent waste-to-energy material due to its versatility. Municipal solid waste and sewage sludge are two great sources of biomass. The process of charcoal production is eco-friendly and highly efficient, so that the resources are not wasted. It is also possible to get government support by installing a dedusting system. There are many other benefits of charcoal production.

Carbon Content Of Charcoal

Charcoal making machines are the cheapest way to create carbon-rich fuels. Charcoal is the most basic form of biomass used for cooking and heating purposes. Its carbon content is primarily fixed and it contains very little volatile matter. Charcoal is one of the oldest fuels used by humans and it is still widely used around the world as a smokeless fuel or as the feedstock for barbeque pits. The process of charcoal production begins with wood stacked on the ground and is topped with a clay covering. This reduces the oxygen supply to the wood, but there is a small hole in the clay that provides enough oxygen for carbonization.

Charcoal is used for cooking, drying, and for electric generation. The carbon content of charcoal produced by a biochar production equipment varies depending on its application. Depending on the type of organic materials, it may contain a range of between fifteen and thirty percent carbon. Charcoal making machines are designed to meet the needs of different users and can accommodate a wide range of biomass types. To produce charcoal, the raw materials should be crushed and dried, and then put into the carbonization furnace via a conveyor.

Cost Of A Charcoal Making Machine

A charcoal making machine can help you produce a variety of carbon-containing organic biomass. The biomass materials must be crushed into small chips with a minimum diameter of 10mm and a moisture content of 20 percent. The biomass materials are then carbonized in an anaerobic environment. After carbonization, the biomass materials are discharged as charcoal, wood tar, and wood vinegar. In addition, biomass carbonization technology produces non-condensable gases that can be used in various applications.

The cost of a charcoal making machine varies, depending on the scale of production you intend to achieve. Small models with 500 kg hourly feeding capacities are the least expensive, but are impractical for large-scale production. Additionally, you must consider the labor investment for the machine. The production scale that you choose will determine the amount of workers needed for the machine. For instance, a biomass pyrolysis plant designed for a one ton daily production will require at least two people to run.