Tire waste is a big problem worldwide. While scrap tires can be incinerated to produced heat energy, when they burn, lots of toxic smoke is released into the air. Meanwhile, when tires are sent to landfill sites, they pose a big fire hazard. This is because methane gas can collect in the cavities. Furthermore, a typical road tire takes around 80 years to decompose and during that time lots of toxins are released into the environment. If a landfill lining fails, those toxins can find their way into groundwater and various natural ecosystems.

The good news is that it’s possible to recycle tire waste in a manner that is both economically viable and environmentally sustainable thanks to tyre to fuel recycling plant. In a pyrolysis reactor, tires vapourize as oppose to burning due to the absence of oxygen in the reaction chamber. This means that no smoke is produced and operators don’t have to worry about toxic plant emissions. The oil vapour is then sent through cooling condensing tubes and separated into fuel oils of varying viscosities. Combustible gases are also collected. In many setups, however, instead of collecting the combustible gases extracted in tanks, the gases are used to refuel the reactor. As a result, the running costs can be kept to a minimum.

Tire Pyrolysis End Products

The reasons why tire recycling businesses have great annual project potential is because the end products from rubber tire pyrolysis are sought-after by mean industries. Carbon black, for example, can be sold to the pharmaceutical, tire manufacturing, and chemical industries. Alternatively, it can be converted into fuel briquettes. You can read one of the latest waste tyre pyrolysis plant project report to get an idea as to your expected profits.

According to many tyre pyrolysis plant project reports published online, many national governments offer large grants, tax-rebates, interest-free loans, and green subsidies to businesses in the rubber waste recycling industry. Therefore, you should always check with your own government, as you may be able to access funding to help cover equipment costs. Such bursaries and grants can help to significantly reduce the initial investment costs for those just getting started in the tire recycling field. Given the fact that mounting tire waste presents a global environmental challenge, it’s not hard to understand why businesses investing in pyrolysis plants (https://bestonpyrolysisplant.com/) to deal with the waste in eco-friendly ways are being offered extra funding.

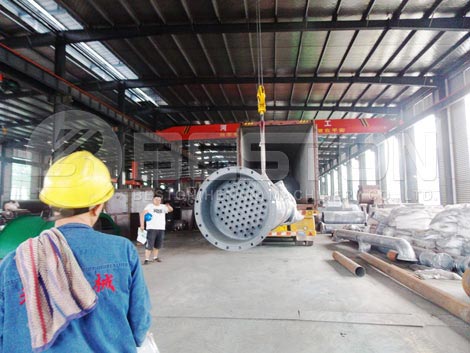

Tire Recycling Plant Suppliers

Arguably one of the best ways to save money on rubber pyrolysis machinery is to compare price quotes from a selection of domestic and overseas suppliers. Fortunately, you can generally get a price estimate within 24 hours by contacting a supplier through their website. Requesting a tire to oil machine price quote doesn’t mean you have to place an order, so you have nothing to lose by comparing prices from a range of vendors. That said, the most important thing is to ensure you buy high-quality waste tyre pyrolysis machine from a reputable source. Always investigate the reputation of a seller before handing over any cash.