The egg tray machine is one versatile piece of equipment. It works in a unique way to produce egg trays. It can also create trays for storing shoes, fruits, and coffee cups by employing different molds. It assumes a four-step production mechanism. Each stage is dependant on the other. Thus a need for crucial attention to detail. If you go shopping, you will encounter variations of the egg tray machine in the market. Each of them is suitable but for different work set-ups. However, all of them allow a similar mode of production as follows.

Pulping

Pulping refers to forming a consistent mix using the raw materials. The machine uses waste paper as the primary raw materials. These include old carton boxes, books, and newspapers. The investor can get this on a small scale from households. Also, recycling companies who deal with similar materials can offer on a large scale. The initial step of pulping involves mixing the waste paper with water. There is a pulp beater that mashes and beats the mix to eliminate any lumps. The output has to be smooth and consistent. Otherwise, the end product becomes substandard. Also, it is imperative to add appropriate proportions of both products. The mix should neither be too thick nor runny. Click here to know more about Beston Machinery.

The second phase of production is molding. Once the mix attains the desirable state, it gets conveyed to the next stage through pipes. The molding system consists of gadgets to help shape different forms and sizes depending on the need. The pipes discharge the mix on these gadgets and cover them entirely. When the process completes, a vacuum pump will suck the air from forming egg trays to take the molds’ exact shape. Also, it helps in the removal of excess water from the molds. The last step includes an air compressor detaching the items by blowing air on them.

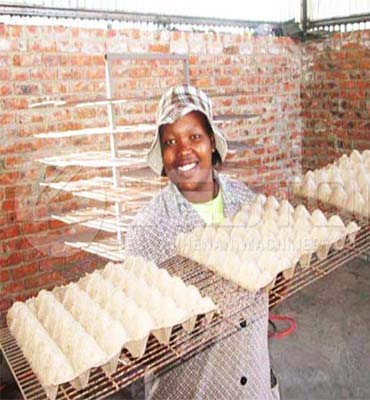

Drying

Drying is a vital process of the egg tray machine. There are different options that an investor could choose. All of them are, however, ideal but depending on a couple of factors. The first is the quantity of production and second your budget. The first option is natural, also called sun drying. Since it depends on the sun, it is free. However, it comes with inconveniences and is not suitable for large-scale production. The other two options include brick and metal drying systems fitted with conveyor belts. These two are the best in this category. Depending on your choice, sufficiently dry the egg trays until there’s no trace of dampness. Also, you can know the fruit tray making machine here.

Packaging

The last step is packaging and transportation. There is a hot press where all the trays go through to get a defined and similar shape. Also, it allows for the removal of air spaces and the stacking of large numbers in one box.

As seen above, the egg box making machine is one lucrative investment. The demand for the end products is constantly increasing both industrially and locally. Choosing it is a gateway to making profits within a short period.