Waste processing facilities around the world are embracing the lastest solid waste processing equipment to hit the marketplace. Such equipment is a growing trend in many cities, as populations struggle to deal with mounting garbage that causes a reduction in living standards and environmental pollution. With a modern waste sorting machine, mixed trash can be collected from all households and businesses in a city, including restaurants, hotels, offices, and colleges, and processed into material categories that can be easily recycled. This means that fewer quantities of waste need to be sent to sea fill and landfill sites each year. What’s more, waste processing facility owners can make substantial profits from many recyclables. Contact reputable municipal solid waste treatment plant manufacturer to get this machine. Besides, get a pulp molding machine to recycle paper waste.

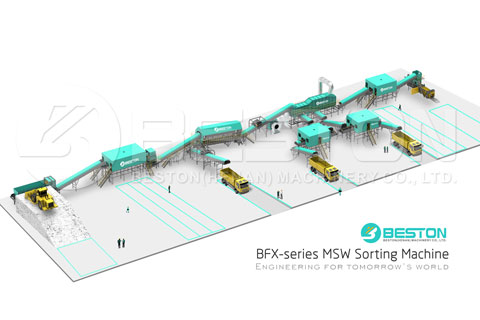

Solid Waste Processing Equipment Working Processes

The four key working processes inside a waste sorting machine including feeding and distributing, manual sorting, further screening, and final processing. When a garage truck arrives at a waste processing facility, all of the mixed trash is unloaded onto the discharge platform before being fed into a machine by a conveyor belt system. The scale plate feeders and uniform distributing machine ensure that waste materials are evenly spaced out on the conveyor belt for efficient processing by different components in the waste recycling machines. The biomass pellet plant is the most effective way to recycle wood.

The basic parameters of solid waste processing equipment sorting machines that buyers needed to take note of include capacity, area, working time and area. You want to choose a machine that is most suitable for your waste management and recycling facility. There is little point investing hundreds of thousands of dollars in a trash sorting machine model with a 20 ton per hour capacity rating if you only need to process a few tons of mixed garbage each week. Some of the smaller 5 T/H capacity models are likely to be more suited to your needs in such a situation.

The end product categories of a typical solid waste processing equipment include paper, metal, plastics, glass, textiles, biomass, construction waste, rubber and more. A pyrolysis machine can be used to convert plastics, rubber and biomass materials into fuel oil. Besides, read tyre pyrolysis project report to recycle waste.

A typical wasting sorting plant for sale will be able to process all types of urban garbage or MSW (municipal solid waste) and have a daily processing capacity ranging from 100 to 400 tons assuming it runs for 16 hours each day. The feeding style of a basic model will by batch loading via shovel, and power consumption varies from 225KW to 294KW.