Crude oil sludge is derived from drilling, exploration, and refining oil resources. It is made up of water, sludge, and oil, which often increases environmental pollution when not processed properly. However, oil sludge also boasts a lot of valuable oil, which offers an attractive income opportunity to a variety of investors. This is why so many companies have decided to invest in oil sludge pyrolysis plant.

Unprocessed oil sludge is hazardous to our environment, which is why treatment of these substances is an excellent investment for government, non-government, and private organizations.

Available Options With Oil Sludge Treatment Plants

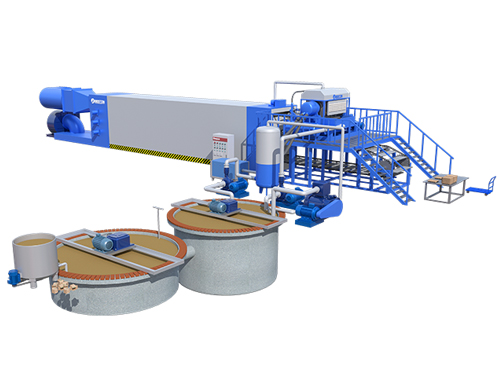

An oil sludge treatment plant includes an automated feeding system. It also uses a direct condensation method that assists with cooling gas into a liquid. The exhaust gas and wastewater are all processed in a special machine to prevent environmental pollution, which makes this device safer for the surrounding environment.

Tire pyrolysis equipment also include an automated warning device and pressure gauge, making certain these machines are safe to use.

How Does A Pyrolysis Plant Help To Treat Oil Sludge

Oil sludge is a result of by-products caused by oil refineries and drilling. It is also made up of oil and water. Oil sludge pyrolysis plants assist with separating the water and oil sludge out of the oil, to make the oil usable again. Pyrolysis plants are able to produce premium-quality fuel oil. The recycling oil sludge plants include an oil condenser, hydro-seal, de-casting system, oil tank, and pyrolysis reactor.

Oil Sludge Treatment Plant Designs

The main components associated with exhaust gas that cannot be liquefied include class c1 and c4 alkanes. When directly burning these alkanes they pose plenty of hazards and dangers. Most of the oil sludge treatment devices feature a design that makes sure the gas passes through a water seal. The gas is then trapped in the 1st seal device before they are used as fuel.

The hydro-seal helps to stop any flames from burning back and to remove impurities, sulfur, and to clean the desulfurization gas. These plants include precise pressure and thermometer gauges that monitor the pressure and temperature. Get the machines from this page https://bestonmachinery.com/pyrolysis-plant/small/.

The latest oil sludge pyrolysis plants sold by a number of reliable manufacturers, use third-generation heating methods that combine some of the greatest benefits of both indirect and direct heating techniques, which ensures a much safer operation.

Conclusion

The oil sludge recycling pyrolysis plants are currently available in 3 types. These include the fully automatic oil sludge pyrolysis plants, the half-automated or semi-automatic oil sludge recycling plants, and the batch pyrolysis oil sludge treatment plants. The best type that will match up to what you need is usually determined according to your budget and requirements. The crude sludge oil treatment plants are now available at a range of cost of pyrolysis plant.

You also won’t be required to spend many hours training your staff on how to work these machines. This machinery is designed to rapidly extract oil, which means once extracted it is also far easier to remove the usable oil.