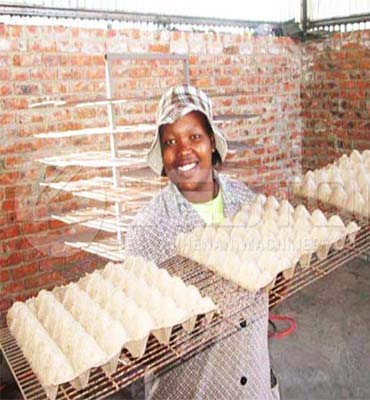

It’s good to figure out what a good pulp egg tray machine is before you spend anything on one. You’re going to find that there are good and bad options to select from. It’s wise to take your time with this, so you get what you know is going to benefit you the most.

Read up on the machine(maquina de hacer maples de huevo) to get a feel for how to work it before you run it the first time. It’s smart to learn all you can about how to operate it, so you don’t make a mistake that causes the machine to break down on you. There are going to be times when you may not know what you’re doing, which is why finding a manual of some kind is a good idea. You want to know how to work the machine well so in the end you’re happy with how everything turns out for you.

Before you buy a machine(https://www.bestoneco.com/maquina-para-fabricar-cubetas-de-huevos/), see if you’re able to return if it there are any issues going on. For instance, if you try to run it the first time and it just doesn’t work as it should, you need to know that the seller will work with you. They need to either be able to give you a refund or they need to get a new machine out to you without you having to buy another. You don’t want to work with a seller that says all sales area final because then you may get stuck with a bad machine in general.

Know the dimensions or the machinery you’re going to buy so you know where you can put it. You always want to go with a machine that will have room around it because if it’s a very tight fit then it may be hard to get around the machine(máquina para hacer cartones para huevos). If you’re not sure how big something like this is, then ask the seller to measure it for you so they can let you know what you’re thinking of buying. There are going to be options of all sizes out there so if you don’t find something that will work at first, keep shopping around.

Seek out an egg tray machine(venta de maquinaria para reciclaje) that has some kind of coverage associated with it, like through a warranty. If you have to pay a bit extra to get the machine covered, it’s generally worth it. The reason why this is such a good idea is that when you have a warranty, you don’t have to worry about the machine breaking down or having issues in general. You don’t want to get stuck with a broken machine, so go with one that you have options with in case something bad happens to it.

Now is the time to buy the best pulp egg tray machine possible. Since you have many options, it’s a smart idea to shop around a bit at first.