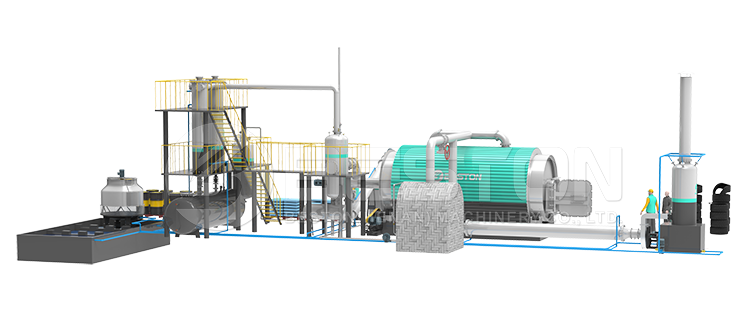

If you are in the egg tray industry, then you will be interested in the paper egg tray making machine from Beston Company(машина для изготовления бумажных лотков для яиц от компании Beston). It is something that will make your job a lot easier. Since this is a tool that you will be able to use for a long time to come, you should look into it.

Buy Paper Egg Trays Making Machine From Beston Company

The paper egg trays making machine that Beston Company makes is of good quality. You will find that it is worth the money that they are charging. It will allow you to do more with your business. Make sure that you look into it further. Ask a lot of questions about it and how to care for it. You want to make sure that you take care of it properly. It will definitely be a plus for you to have one of these.

When You First Start Out In Your Business

When you are first starting out in your business, you may need some tips that will help you to do really well at it. Here are some tips that you should keep in mind:

1. Know How Much Money You Have

You want to have money to invest in your company. Be sure that you have a budget set up for this type of thing. You will want to write it all down so that you know if you can afford the machine from the Beston Company.

2. Understand Your Competitors

Figure out what your competitors are doing. You want to know what type of machine they are using and other incidentals about how they are operating their business. Don’t set your prices too high because you will not get the business that you want.

3. Market Yourself Well

You will want to have a great marketing plan in place. This has to do with advertising and the presence you have online. Make sure that your website is up to par. This will help to attract the customers to you.

4. Find Your Target Market

Know who you want to talk to. In the beginning, you will want to talk with the smaller companies. As you move on, you can talk with the larger companies too. You will be able to branch out in more directions after you have been in the industry for a while.

Your business will do very well. Once you use the tips above, you should be able to do more and increase your profits. It is a good idea to invest in the paper egg trays making machine from the Beston Company. It will help you in many ways. Set your goals for your company realistically and know that you will continue to do better and better as time moves on. Since this is what you want, you will have quite a business of your own that you can be extremely proud of. Make sure that you always concentrate on what needs to be done each and every day.