The burgeoning issue of plastic waste necessitates not just innovative solutions but an unwavering commitment to optimizing existing processes. Within the realm of waste management, the plastic pyrolysis machine has emerged as a notable contender, presenting a viable avenue for converting plastic waste into valuable resources. To delve into the intricacies of this process, it is imperative to scrutinize a critical component: the role of combustible gas recovery and its consequential impact on the efficiency of plastic pyrolysis.

Understanding the Plastic Pyrolysis Machine

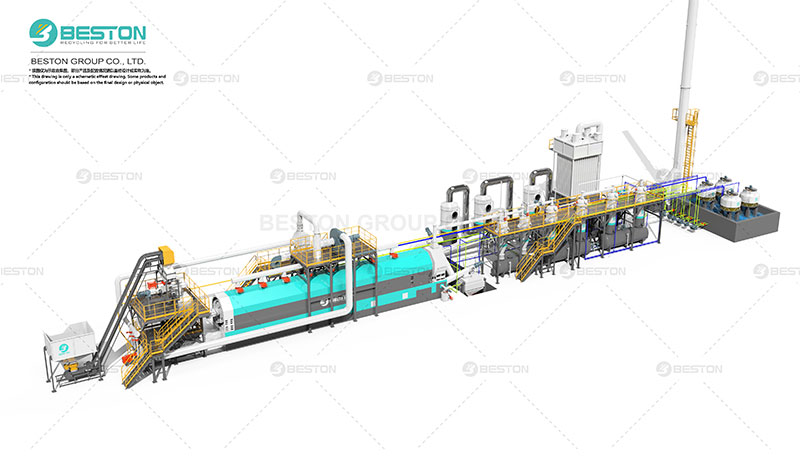

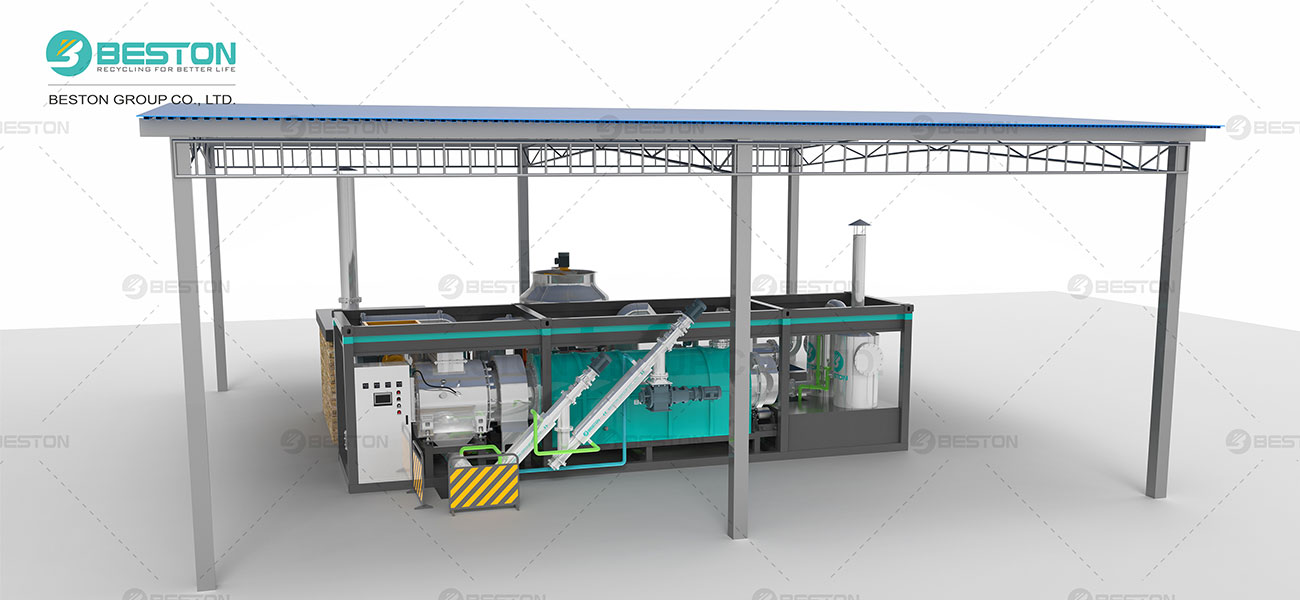

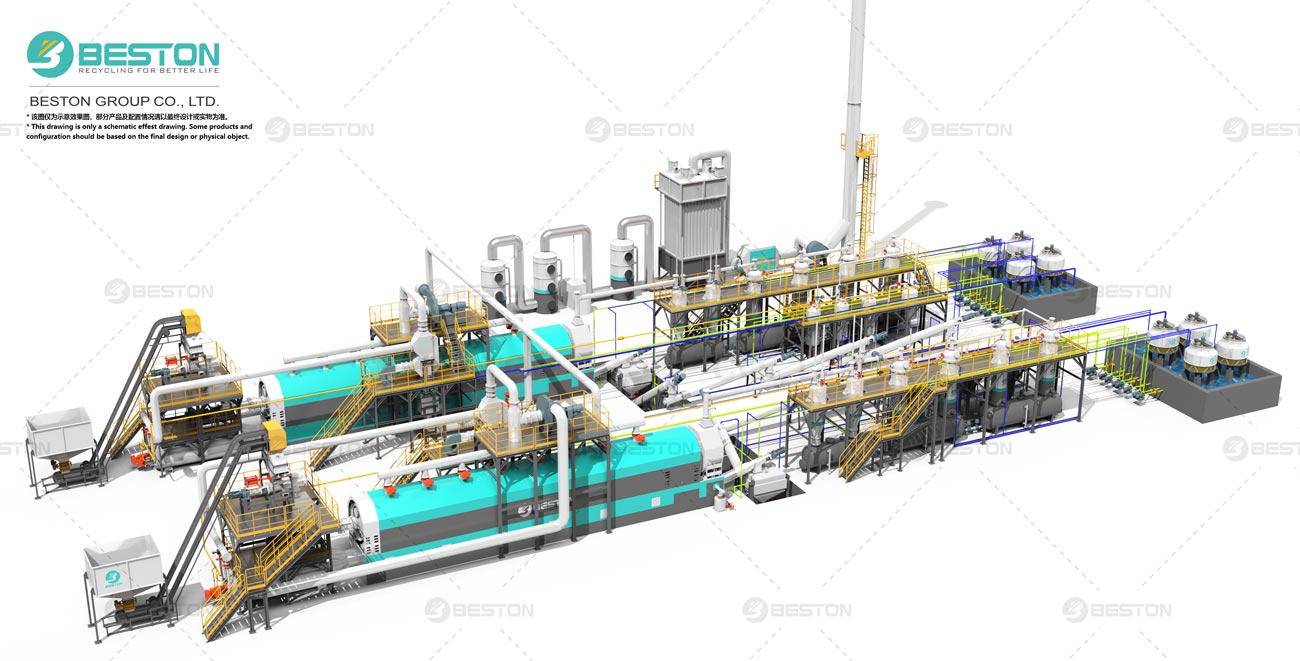

A fundamental aspect of the plastic pyrolysis process revolves around the plastic pyrolysis machine. This sophisticated apparatus operates on the principles of thermal decomposition in an oxygen-deprived environment. The resultant outputs include liquid fuel, solid residue, and combustible gases. At the core of this machinery lies the capability to unlock the latent energy within plastic waste, transforming it into a resource-rich venture.

Continuous Pyrolysis Machine Integration

To fortify the plastic pyrolysis process, the integration of a continuous pyrolysis machine stands as a strategic imperative. Unlike batch processes, a continuous system ensures an uninterrupted flow of plastic feedstock, thereby optimizing operational efficiency. This perpetual feed mechanism not only streamlines the process but also caters to the demands of high-throughput scenarios.

The Crucial Role of Combustible Gas Recovery

Amidst the triumvirate of outputs from plastic pyrolysis, combustible gases often find themselves relegated to the shadows. Yet, their recovery proves to be a linchpin in the quest for heightened efficiency. Primarily composed of hydrocarbons such as methane and ethane, these gases, if harnessed effectively, contribute significantly to both environmental sustainability and resource optimization. At present, Beston Group‘s pyrolysis equipment has a mature combustible gas recovery process, and you can consult directly if you have relevant questions.

The recovery of combustible gases is not merely an ancillary process; it is a transformative endeavor that converts what could be considered waste into a valuable energy resource. This reclamation process involves the systematic capture, purification, and reintroduction of these gases into the energy production cycle.

Thermochemical Dynamics

To comprehend the profound impact of combustible gas recovery, one must delve into the thermochemical intricacies transpiring within the plastic pyrolysis chamber. As plastics undergo thermal cracking in the absence of oxygen, they liberate a spectrum of gases. The efficient recovery of these gases ensures a closed-loop system, mitigating emissions and fostering a regenerative approach to waste management.

Within the operational domain of a continuous pyrolysis machine, combustible gas recovery assumes heightened significance. It establishes a cyclical harmony wherein the gases expelled during pyrolysis are not discarded but redirected back into the process. This closed-loop approach is pivotal, transforming a linear waste disposal process into a sustainable and resource-efficient system.

Optimization through Gas Utilization

The recovered combustible gases, often dismissed as byproducts, play a pivotal role in sustaining the elevated temperatures required for optimal thermal cracking. Functioning as both a catalyst and a source of energy, these gases serve to perpetuate the pyrolytic reactions, ensuring a self-sufficient and energetically economical process.

In essence, the integration of combustible gas recovery systems into the plastic pyrolysis matrix is a testament to the synergy between environmental responsibility and technological advancement. It transcends the conventional paradigms of waste management, positioning plastic waste as a reservoir of untapped potential rather than a predicament.

Conclusion: A Paradigm Shift in Waste Management

As we contemplate the symbiotic relationship between the plastic pyrolysis machine, continuous pyrolysis integration, and the strategic recovery of combustible gases, a paradigm shift in waste management becomes evident. This shift extends beyond the mere treatment of plastic waste; it underscores a broader ethos of repurposing and optimizing resources.

The effect of combustible gas recovery on plastic pyrolysis efficiency is not a peripheral consideration; it is a transformative force in the ongoing battle against plastic pollution. By elevating the efficiency of plastic pyrolysis processes, we not only address the immediate challenges posed by plastic waste but also pave the way for a sustainable future where waste is redefined as a valuable resource waiting to be reclaimed.