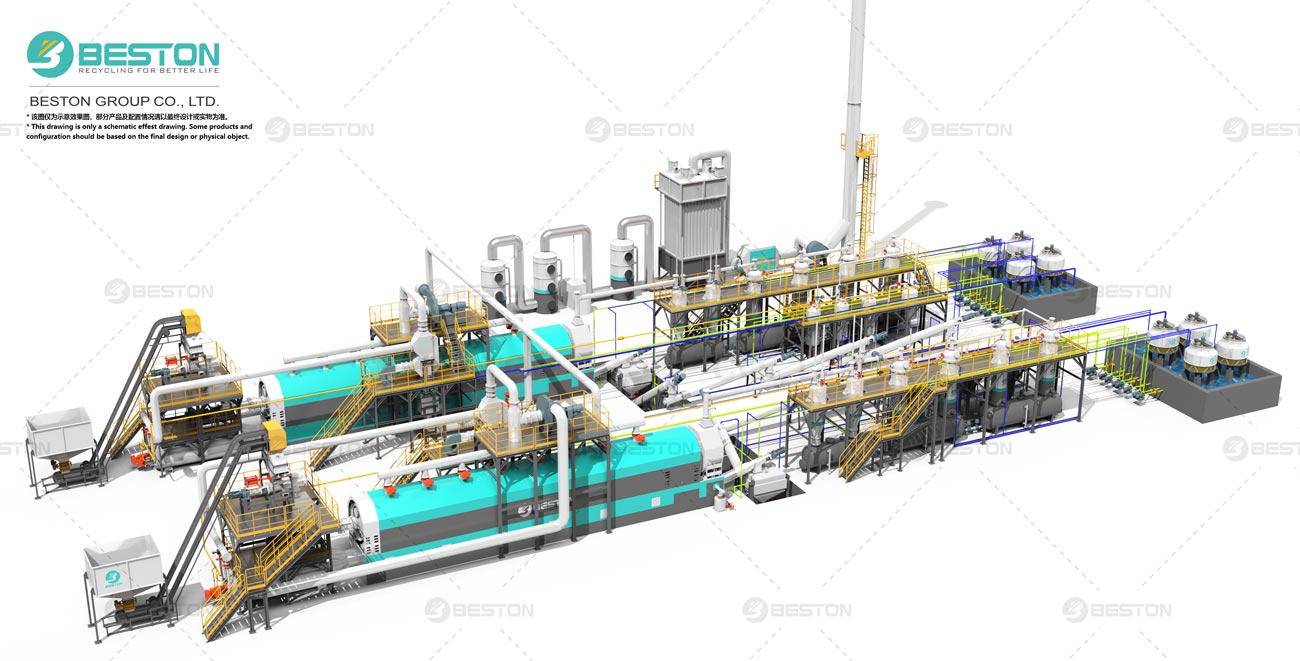

A carbonization machine is a device used to convert organic waste material into charcoal. This process is also known as pyrolysis. The machine heats the material in an oxygen-free environment, causing it to break down into its component parts. The end product of this process is a carbon-rich substance that can be used as fuel or for other industrial purposes.

Carbonization machines are becoming increasingly popular as a way to reduce the amount of organic waste that goes to landfills. They are also being used to produce charcoal for barbecues and grilling. When used correctly, carbonization machines can be an effective way to reduce environmental pollution.

How to use a carbonization machine

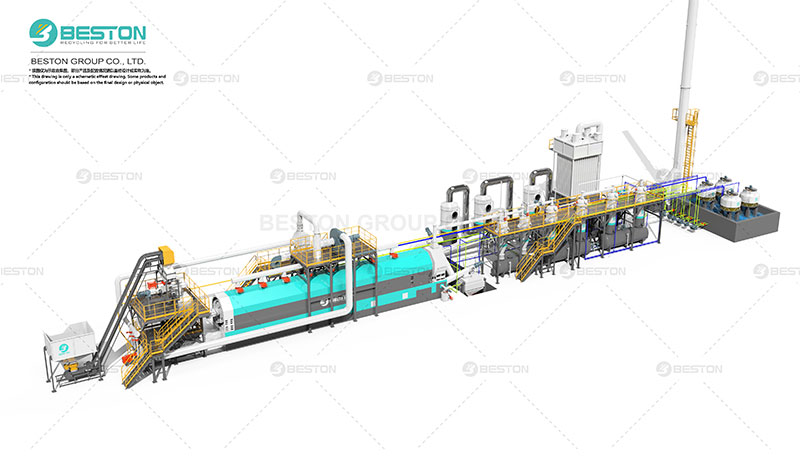

While there are many different designs, the basic principle is the same: wood is placed in a chamber and heated to a high temperature, typically around 700 degrees Celsius. This process causes the wood to release gases and produce charcoal. The charcoal is then cooled and can be used as fuel.

When using a carbonizer machine, it is important to ensure that the chamber is properly ventilated. Otherwise, the gasses produced by the burning wood can build up and explode. In addition, it is important to monitor the temperature carefully to avoid damaging the machine or causing a fire. With proper care and attention, a carbonization machine can be a useful tool for producing charcoal.

Why you should invest in a carbonization machine

If you’re looking for a way to reduce your carbon footprint and help the environment, investing in a charcoal kiln for sale may be a good option. Carbonization offers a number of benefits. For one, it helps to sequester carbon dioxide from the atmosphere, preventing it from contributing to climate change. Additionally, it can be used as a fuel source, which can save you money on energy costs. And finally, the process of carbonization can actually improve the quality of the soil, making it more fertile and productive.

There are a number of different types of carbonization machines available on the market, so it’s important to do your research to find one that best suits your needs. But if you’re serious about reducing your impact on the environment, investing in a carbonization machine is definitely worth considering: https://bestonasia.com/charcoal-making-machine-price/.

How to care for your carbonization machine

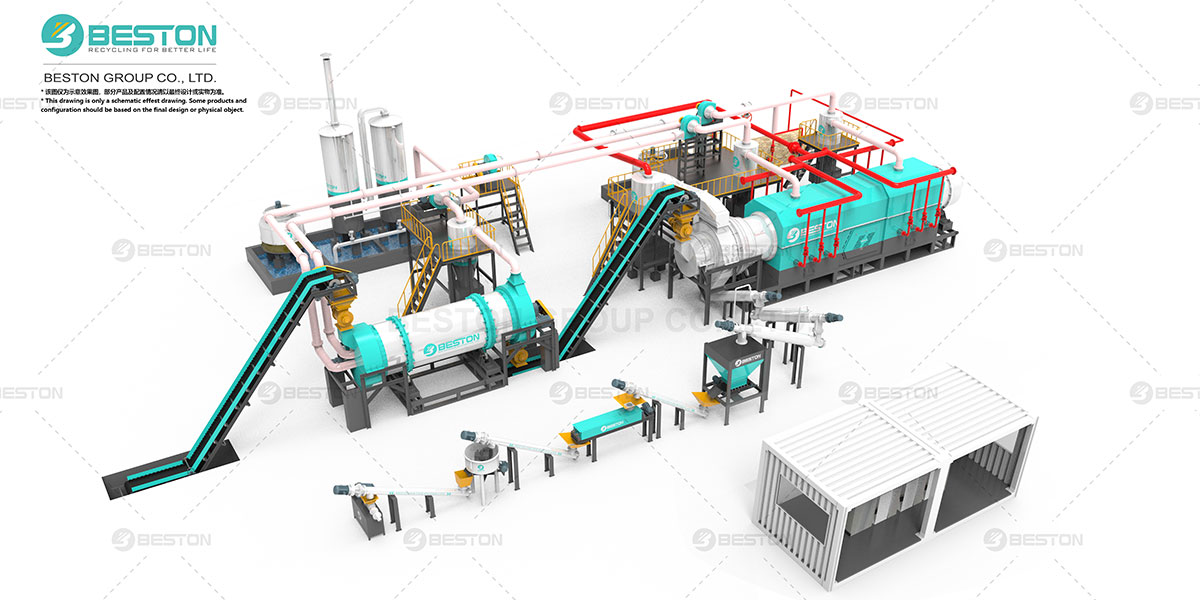

A carbonization machine is an incredible investment for many business owners. Not only does it allow you to produce high-quality charcoal, but it also requires very little maintenance. You can expect low overhead costs, even if you’re new to using this piece of equipment. However, there are a few things you should keep in mind to ensure that your machine runs smoothly and efficiently.

First, always use clean wood when loading the carbonization chamber. This will help to prevent clogs and increase the efficiency of the combustion process. You also need to clean the ash from the chamber after each use. Check the tightness of the lid periodically to make sure that no air is leaks. By following these simple tips, you can keep your portable biochar machine in top condition for years to come.