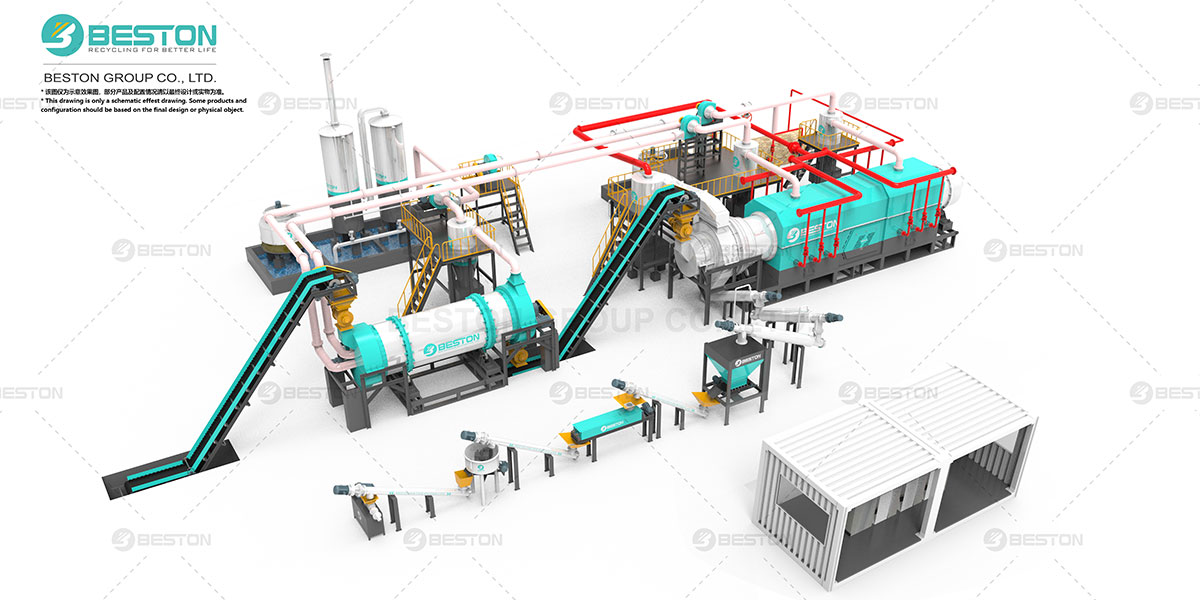

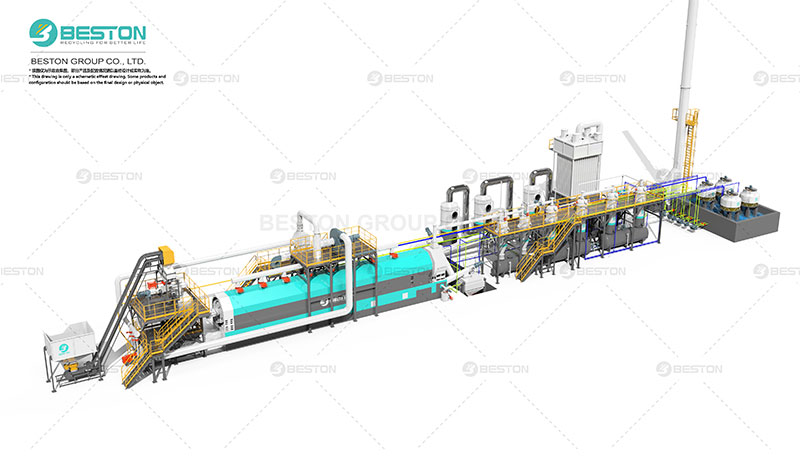

Tire pyrolysis plant can recycle various waste materials into different forms such as oil, steel wire, and waste plastics. In addition, you can use the processed tires for various purposes including gasoline, diesel, and ceramics. There are also several industrial applications of these plants, including steel, iron, boilers, and ceramics.

Carbon Black

The waste tire pyrolysis project(planta de pirolisis) aims to convert the oil from waste tires into carbon black, a highly valuable feedstock used in the manufacture of tire, rubber, ink, toner, and paint. The pyrolysis plant has been in operation for several years, but has not yet reached commercial production scale due to the low economic leverage of the end products. Reprocessing waste tires would increase economic leverage.

Oil

By using waste tire pyrolysis oil, Drum will produce high-quality fuel that is similar to that of primary fossil resources but has a lower carbon footprint. The oil, which is extracted from waste tires, can be used to produce fuel for engines, diesel generators, heavy machinery, and heating fuel. According to a Life Cycle Assessment (LCA) study conducted by Sphera, a chemical company(Bestongroup), one ton of PA6 produced from Pyrum waste oil would emit 1.3 tons of CO2 compared to a ton of fossil feedstock.

Steel Wire

The steel wires found inside tires account for around ten percent to fifteen percent of the total weight of the tire. The process of pyrolysis breaks these steel wires down into useful parts. Once the tires have been recycled, value steel wires are removed and sold to scrap dealers or steel producers. You can request a competitive quote for steel wires for tire pyrolysis plants by filling out a simple form.

Waste Plastics

The pyrolysis of waste tires(planta pirolisis llantas) will produce valuable fuel oil, which can be refined into diesel, as well as other chemical products. The oil from pyrolysis can be used to make steel wire and carbon black. It is a renewable and environmentally friendly source of raw material for the automotive industry. The plant is designed for industrial scale production. Waste tires are commonly recycled into plastics that are used to make car tires.

Reprocessed Into Diesel and Gasoline by Waste Oil Distillation Machine

Waste oil can be refined into gasoline and diesel with the help of a waste oil distillation machine at a tire pyrolysis plant. This machine uses high-temperature distillation to extract the oil from waste tires. The process also involves deodorization and clay decolorization. This machine can refine waste oil from a wide variety of sources, including plastics, tires, rubber, oil sludge, and medical waste.

Reprocessed Into High Quality Carbon by Carbon Black Processing Plant

Reprocessed tires, a waste product of the automotive industry(https://www.bestoneco.com/planta-de-pirolisis-en-mexico/), are ideal candidates for reprocessing into high-quality carbon black. The pyrolysis process uses high temperatures and absence of oxygen to produce carbon black and other volatile gases. While unfilled raw recovered carbon black has low value, refined carbon black is twenty times more valuable. This technology is also beneficial for the environment, as it saves more than one million trees worldwide.